Resin is a fantastic material for crafting and DIY projects. It’s durable, versatile, and has a beautiful glossy finish. However, if you’ve ever worked with resin, you know that getting rid of sticky residue can be quite a challenge. Whether you’re dealing with cured epoxy resin or sticky UV resin, it can be frustrating when your finished project doesn’t turn out as smooth and polished as you’d hoped.

In this blog post, we’ll explore various methods for removing sticky residue from resin. We’ll cover everything from why resin can become sticky to practical tips for dealing with cloudy or tacky finishes. So, whether you’re a resin enthusiast or just starting out with this fascinating material, read on to discover how to achieve that perfect, flawless finish.

How to Banish Sticky Residue from Your Resin Creations

So, you’ve just finished creating a beautiful resin piece, but now you’re left with an unwelcome visitor: sticky residue. Don’t worry, though – we’ve got your back! In this guide, we’ll explore some tried-and-true methods to help you bid adieu to that pesky stickiness and restore your resin creation to its former glory. Say goodbye to sticky situations and hello to a resin masterpiece that’s smooth to the touch!

Cleaning with Soap and Water

Get Sudsy to Get Rid of the Stickiness

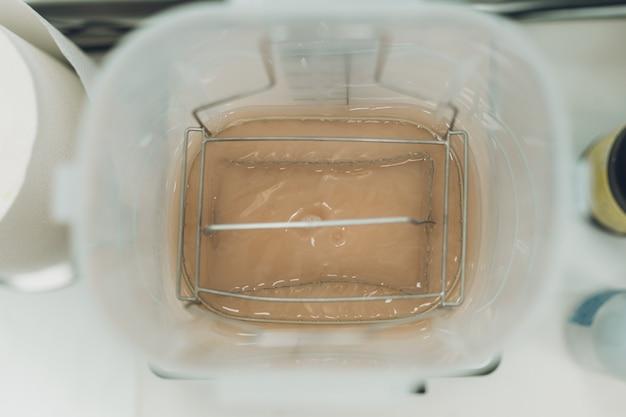

One of the simplest ways to tackle sticky residue on resin is by washing it with soap and water. Start by filling a sink or basin with warm water and add a few drops of dish soap. Give it a good swirl to create a soapy solution that’s ready to battle the stickiness.

Scrub-a-Dub with a Soft Cloth

With your soapy solution ready, grab a soft cloth or sponge and dip it into the mixture. Gently but firmly rub the sticky areas of your resin creation, using circular motions. The soap will work its magic, breaking down the residue and making it easier to remove.

Rinse and Dry Thoroughly

Once you’re satisfied with the scrubbing, rinse off the soap under warm running water. Be sure to remove all traces of soap from the resin. Pat dry with a clean towel or let it air dry completely. Voila! Your resin creation should now be residue-free and ready to shine.

Removing Stickiness with Isopropyl Alcohol

Alcohol: Resin’s Best Friend

When soap and water just don’t cut it, it’s time to call in the big guns – isopropyl alcohol. This powerful solvent can effectively dissolve sticky residue without harming the resin itself. Just make sure you’re using a concentration of at least 70% to ensure maximum efficacy.

Dab and Swab

To get started, dampen a cotton swab or a lint-free cloth with the isopropyl alcohol. Gently dab the sticky areas of your resin creation, applying a bit of pressure as needed. The alcohol will break down the sticky residue, making it easier to wipe away.

Wipe Away the Troubles

Once you’ve dabbed away the stickiness, take a clean cloth or paper towel and wipe the residue clean. Repeat this process as necessary until all the stickiness is gone. Just remember to handle the alcohol in a well-ventilated area, as its fumes can be quite potent.

The Magic of Baby Oil

Baby Steps to a Sticky-Free Surface

If you’re looking for a gentler alternative to harsh solvents, baby oil might just be your knight in shining armor. Not only will it banish the stickiness, but it will also leave a lovely, glossy finish on your resin creation.

A Tiny Dab’ll Do Ya

To use baby oil, simply apply a small amount onto a cloth or cotton swab. Gently rub the sticky areas of your resin creation, allowing the oil to work its magic. As you do this, you’ll notice the stickiness melting away like a summer popsicle on a hot day.

Buff to Perfection

Once you’ve thoroughly applied the baby oil and banished the sticky residue, take a clean cloth and give your resin creation a gentle buff. This will remove any excess oil and leave your piece with a beautiful sheen. Now you can proudly display your sticky-free creation for all to admire!

Sticky residue may seem like a formidable foe, but armed with these tried-and-true methods, you’ll be able to conquer it and restore your resin creations to their former glory. Whether you choose the power of soap and water, the might of isopropyl alcohol, or the magic of baby oil, say goodbye to stickiness and hello to a resin masterpiece that’s as smooth as silk. Enjoy your sticky-free resin adventures in 2023 and beyond!

FAQ: How to Get Rid of Sticky Residue on Resin

Why is my UV resin cloudy?

If you’re finding your UV resin to be cloudy, it’s likely due to improper curing. Cloudiness can occur if you haven’t exposed the resin to enough UV light, or if there’s a presence of moisture during the curing process. Make sure to follow the manufacturer’s instructions, provide adequate UV exposure, and keep your work area dry for clear and beautiful results.

What is plant resin?

Plant resin is a sticky substance secreted by plants to heal wounds and protect themselves from pests and diseases. It is commonly known for its use in creating amber. Plant resin has been used for centuries in various applications ranging from ancient medicine to jewelry making. If you are using plant resin for your crafts, it’s important to note that removing sticky residue will differ slightly from other types of resin.

How do you make sticky resin in IndustrialCraft?

While IndustrialCraft offers various methods for crafting items, creating sticky resin is not one of them. Sticky resin is typically associated with the natural sap from trees or the stickiness that can develop on resin-based art or crafts. So, unfortunately, you won’t be able to make sticky resin directly in IndustrialCraft.

What dissolves cured epoxy resin?

Once epoxy resin has cured, it becomes a hard and durable material that can be challenging to dissolve. However, there are some solvents that can help break it down, such as acetone or isopropyl alcohol. Keep in mind that these solvents may also affect the underlying surface, so test in a small, inconspicuous area before applying them extensively.

How do you remove sticky residue from resin?

To remove sticky residue from resin, it’s best to start with a gentle approach. One method is to use warm, soapy water and a soft cloth to gently scrub the affected area. If that doesn’t work, you can try using isopropyl alcohol or nail polish remover, making sure to test them on a small area first. Remember to wear gloves and work in a well-ventilated area when using these chemicals.

Do you need to wear a mask when using UV resin?

While wearing a mask is not always mandatory when using UV resin, it is highly recommended, especially if you are working in a poorly ventilated area or if you are sensitive to strong odors. A mask with activated carbon filters can help protect you from any potential harmful fumes that may be emitted during the curing process.

How do you fix foggy resin?

Foggy resin can be frustrating, but fear not, there are ways to fix it! To fix foggy resin, you can try sanding the surface with progressively finer grit sandpaper, starting with a rough grit and working your way up to a finer one. After sanding, apply a clear coat of resin or resin polish, then cure it properly using UV light or the appropriate curing method for your resin.

How do you fix sticky epoxy?

If your epoxy is still sticky after curing, there are a few steps you can take to salvage your project. First, try applying heat to the sticky areas using a heat gun or a hairdryer on a low heat setting. Gently heat the surface until the epoxy becomes more pliable, and then use a plastic scraper or your fingers to remove the sticky epoxy. If this doesn’t work, you may have to sand down the sticky epoxy and reapply a new layer, making sure to follow the manufacturer’s instructions for proper curing.

Can epoxy cure in 48 hours?

The curing time of epoxy can vary depending on the specific product and environmental conditions. While some epoxy formulations may claim to cure within 48 hours, it’s essential to follow the manufacturer’s instructions for the specific epoxy you’re using. Factors such as temperature, humidity, and the thickness of the epoxy layer can impact the curing time. It’s always best to be patient and allow sufficient time for the epoxy to cure properly.

Why is my resin still sticky?

If your resin is still sticky after the recommended curing time, it could be due to several factors. Insufficient curing time, improper mixing ratios, or an incorrect curing temperature can all contribute to sticky resin. Make sure to follow the instructions provided by the resin manufacturer meticulously, ensuring proper mixing, curing conditions, and adequate curing time. If the issue persists, reaching out to the manufacturer for guidance can be helpful.

How do you make sticky resin in Tekkit?

In the world of Tekkit, sticky resin takes on a different meaning. In Tekkit, sticky resin is a specific item obtained by tapping rubber trees using a Treetap. This resin is a key ingredient in essential materials such as rubber, sticky pistons, and electrical cables. By placing a Treetap on a rubber tree trunk, you can collect sticky resin and use it for various purposes in your Tekkit adventures.

Why is my UV resin sticky after drying?

If your UV resin remains sticky after the drying process, there are a few factors to consider. Firstly, ensure that you’ve given the resin enough UV exposure to cure properly. Insufficient curing time can lead to stickiness. Additionally, make sure you’re using a high-quality UV resin and following the manufacturer’s instructions precisely. If the resin continues to remain sticky, it’s possible that the resin itself has expired or may not be suitable for the desired application.

Where can I find sticky resin?

Sticky resin can be found in various places depending on the context. In the realm of crafting and jewelry making, sticky resin can sometimes develop on resin-based art or crafts due to improper curing or handling. In Tekkit, sticky resin can be obtained from rubber trees by using a Treetap. However, finding naturally occurring sticky resin can be quite rare, and it’s usually easier to purchase from craft stores or online retailers specializing in resin and jewelry-making supplies.

Can you fix bendy resin?

If you find that your resin has turned out bendy or flexible instead of solid and rigid, fixing it can be a bit tricky. Unfortunately, once resin has fully cured, it’s challenging to reverse its properties. However, you can attempt to reinforce the bendy resin by adding another layer of properly mixed and cured resin on top. This should help to add strength and rigidity to the piece. Always follow the manufacturer’s instructions when adding additional layers of resin.

Can you over cure UV resin?

While it’s difficult to over cure UV resin to the point of causing immediate harm, excessive exposure to UV light can lead to other issues. Over curing can result in yellowing or discoloration of the resin, as well as increased brittleness. It’s best to follow the recommended curing time specified by the manufacturer and avoid leaving the resin under UV light for an extended period. Be mindful of achieving the desired hardness and clarity without exceeding the necessary curing time.

Can you put polyurethane over sticky epoxy?

Yes, you can apply polyurethane over sticky epoxy surfaces. Polyurethane can serve as a protective layer, providing additional durability and enhancing the appearance of your epoxy-coated surfaces. Before applying polyurethane, ensure that the sticky epoxy has fully cured, and any unevenness or stickiness has been resolved. Follow the manufacturer’s instructions for the polyurethane product, including proper surface preparation and application techniques, to achieve the desired result.

How do you clean sticky epoxy resin?

Cleaning sticky epoxy resin can be a bit challenging, but fear not, you can tackle it! Start by scraping off as much sticky resin as possible using a plastic scraper or your fingertips. Next, dampen a cloth or sponge with warm, soapy water and gently wipe the area to remove any remaining stickiness. If the residue persists, you can try using isopropyl alcohol or nail polish remover, testing in a small area first to ensure it doesn’t damage the surface.

How long should epoxy be tacky?

The tackiness of epoxy can vary depending on several factors, including the specific product, environmental conditions, and thickness of the epoxy layer. In general, epoxy should cure within 24 to 72 hours, becoming hard and no longer tacky to the touch. However, curing times can be affected by temperature, humidity, and other variables. It’s always recommended to refer to the manufacturer’s instructions for the specific epoxy you’re using to determine the optimal curing time.