Are you interested in creating intricate and unique resin molds? With the help of a 3D printer, you can bring your designs to life and unlock a world of endless possibilities. Whether you’re a hobbyist or a professional, this blog post will guide you through the process of making resin molds using a 3D printer.

In this comprehensive guide, we’ll answer common questions such as: can you make resin molds with a 3D printer? How expensive is resin for 3D printing? Can you 3D print with silicone? We’ll also address the differences between casting and additive manufacturing, explore various materials for resin molds, and provide tips and tricks for achieving smooth resin prints. So, let’s dive in and discover the exciting world of resin mold making with a 3D printer!

How to Create Resin Molds Using Your Trusty 3D Printer

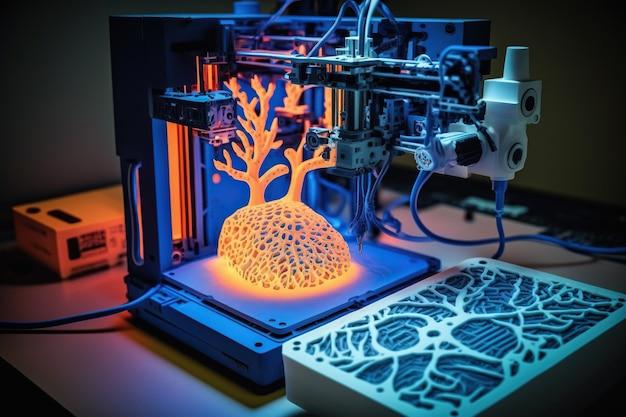

Introducing the Fusion of 3D Printing and Resin Molding

Welcome to the era of resin molding with 3D printers! Gone are the days when you had to rely solely on traditional mold-making techniques. Thanks to the wonders of technology, you can now harness the power of your trusty 3D printer to create stunning resin molds that will make your friends envious and your creative spirit soar. In this guide, we’ll take you through the step-by-step process of making resin molds with your 3D printer, unleashing your inner artist in the process. So, grab your favorite resin and let’s get printing!

Choosing the Right Resin for Your Masterpiece

Before we dive headfirst into the exciting world of resin molding, it’s important to know that not all resins are created equal. It’s vital to select a high-quality resin that suits your specific project needs. You don’t want your beautifully crafted mold to turn into a sticky mess or end up looking like a sad blob. So, do your research, read reviews, and invest in a resin that will bring out the best in your creations. Trust me, your artistic endeavors will thank you later.

Setting Up Your 3D Printer for Mold-making Awesomeness

Now that you have your top-notch resin in hand, it’s time to ensure your 3D printer is ready to bring your designs to life. Make sure you have the right filament loaded, preferably a sturdy and durable material like PLA or ABS. Double-check all the printer settings, so you don’t end up accidentally creating a malformed mold. The last thing you want is a resin blob that resembles something your pet chewed up. Remember, attention to detail here will save you from plenty of unnecessary frustration.

Translating Your Design into a 3D Printing Marvel

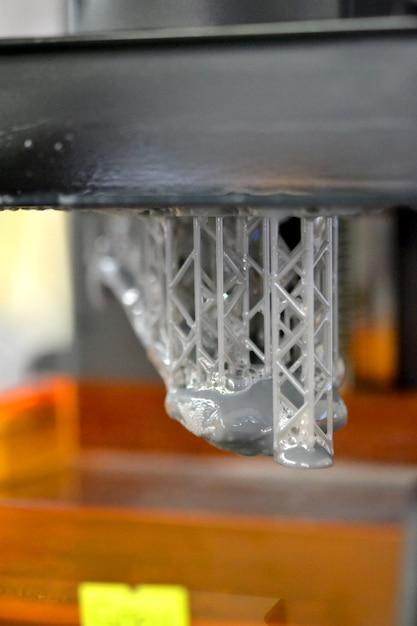

Alright, it’s time for the fun part! Before you begin the printing process, take a moment to admire the design you’ve painstakingly crafted. Remember that sense of accomplishment as you hit that print button because, my friend, you are about to embark on a journey that only a chosen few have experienced – the fusion of 3D printing and resin molding. Watch as your 3D printer brings your design to life, layer by precise layer, while you patiently anticipate the wonders that await you.

Assembling the Pieces: From 3D Print to Resin Mold

Once your 3D printer has completed transforming your design into a tangible object, it’s time for the magic of resin molding to take center stage. Carefully remove the printed piece from the printer, cause smudging your masterpiece at this stage would lead to more frustration than untangling earphone wires on a Monday morning. Now, here comes the part where you’ll feel like a wizard – it’s time to prepare your resin and pour it into your freshly printed mold. Go on, pour it in with a flourish, and relish the feeling of artistic triumph.

The Waiting Game: Patience is a Virtue

Ah, patience, my friend. It’s time to put it to the test. As much as you may be tempted to grab a blow dryer or frantically wave your hands to speed up the curing process, remember that good things come to those who wait. True artistry requires time and dedication. So, leave your mold undisturbed in a dust-free and temperature-controlled environment. Let the resin work its magic, slowly transforming from its liquid form into a sturdy piece of art. In the words of that famous philosopher from the 21st century – “Patience, young padawan.”

Unveiling Your Creation: The Big Reveal

Finally, the moment of truth has arrived! Your resin mold has cured, and it’s time to release it from its 3D printed encasement. With bated breath, carefully separate the mold from the resin, relishing the anticipation of unveiling your creation. And there it is, your masterpiece – a testament to your creativity, ingenuity, and determination. Take a moment to admire it, let the sense of accomplishment wash over you, and then get ready for the next phase of your artistic journey.

The Possibilities are Endless: Let Your Imagination Run Wild

Now that you have mastered the art of resin molding with your trusty 3D printer, a world of endless possibilities lies before you. Experiment with different designs, explore new techniques, and let your imagination guide you towards uncharted artistic territories. It’s time to push the boundaries of what’s possible, break free from the constraints of traditional mold-making, and become the master of your own resin creations. Embrace the artistry and let the resin mold community marvel at your innovative brilliance.

Get Ready to Make a Splash in the Resin Molding World!

So there you have it, aspiring resin mold makers. Armed with your 3D printer and a dash of creativity, you are now ready to take the world of resin molding by storm. Remember, practice makes perfect, and with each mold you create, you’ll refine your technique and unlock new artistic possibilities. Jump into the magical fusion of 3D printing and resin molding, and prepare to make your mark on the world of art and creativity. It’s time to unleash your imagination and let your resin masterpieces dazzle the world in the golden age of molding 2.0!

FAQ: How To Make Resin Molds With a 3D Printer

Welcome to our comprehensive FAQ guide on making resin molds with a 3D printer. We’ve compiled a list of frequently asked questions to help you understand the process, materials, and possibilities of this exciting DIY project. So, let’s dive in and discover everything you need to know!

Can Rubber be 3D Printed

Unfortunately, rubber cannot be directly 3D printed using standard filament-based printers. The flexibility and elasticity of rubber are challenging to achieve with traditional 3D printing materials. However, there are specialized 3D printers known as “resin printers” that can produce rubber-like materials by using specially formulated resins. So, while not exactly rubber, resin printers can create similar flexible objects.

Why is Casting Not Additive Manufacturing

Casting and additive manufacturing are two distinct processes. Casting involves pouring a material, often liquid or molten, into a mold and allowing it to solidify. On the other hand, additive manufacturing, or 3D printing, builds objects layer by layer using materials such as filaments or resins. While both methods can create intricate shapes, they differ in terms of approach and materials used.

Can I Make Silicone Molds With a 3D Printer

Yes, you can use a 3D printer to create molds for silicone casting. By 3D printing a mold design and then pouring silicone into it, you can produce custom silicone molds for a variety of purposes. This opens up endless possibilities for crafting, prototyping, and even small-scale production.

How Expensive is Resin for 3D Printing

Resin prices can vary depending on the brand, quality, and quantity you purchase. On average, a liter of resin for 3D printing can cost around $30 to $50. However, keep in mind that resin consumption depends on the size and complexity of your prints. So, the actual cost will vary based on your specific projects.

Can You 3D Print With Silicone

While silicone itself cannot be directly 3D printed with standard desktop 3D printers, there are specialized silicone-based materials available for use with silicone extrusion printers. These printers operate differently from filament-based printers and can create objects using silicone-based materials. For most DIY enthusiasts, however, using a 3D printer to create molds for silicone casting is a more accessible and cost-effective option.

Is Resin Cheaper Than 3D Printing

The cost comparison between using resin for 3D printing and traditional filament-based printing depends on various factors. While resin itself may seem more expensive than filaments, the amount of material used and the complexity of the print can influence the overall cost. Additionally, resin prints typically have finer details and smoother surfaces, which can reduce the need for post-processing. Ultimately, the cost-effectiveness of resin printing versus filament printing will vary depending on your specific requirements and budget.

What Can I Use to Make a Mold for Resin

When it comes to making a mold for resin, you have several options. Some common materials include silicone molds, 3D printed molds, wood molds, and even food-safe materials like chocolate molds. Each material has its own advantages and considerations, so choose based on your project requirements and the level of detail you need.

Can I Make Resin Molds With a 3D Printer

Yes, you can absolutely make resin molds with a 3D printer. By designing and 3D printing a mold, you can create custom shapes and sizes for your resin casting projects. This method allows for precise and repeatable molds, making it an excellent choice for those looking to unleash their creativity.

Does Cura Have Vase Mode

Yes, Cura, one of the most popular slicing software used for 3D printing, offers a feature called “Spiralize Outer Contour” or “Vase Mode.” This mode allows you to create hollow objects with a single continuous wall, giving them a vase-like appearance. It’s perfect for creating decorative pieces, vases, and other objects with a unique aesthetic.

Can You Make Your Own Resin Molds

Absolutely! Making your own resin molds can be a fun and rewarding process. With a 3D printer, you can design and print molds in various shapes and sizes to bring your creative ideas to life. Whether you are a hobbyist or a professional artist, creating your own resin molds allows for endless possibilities and customization.

Can You 3D Print EPDM

Ethylene Propylene Diene Monomer (EPDM) is a type of synthetic rubber known for its excellent weather resistance and durability. While EPDM is not a material that can be directly 3D printed on standard filament-based printers, there are specialized 3D printers capable of printing rubber-like materials. These printers can produce rubber-like objects from specific filament or resin formulations, introducing exciting opportunities for EPDM-like creations.

Can You Use Epoxy Resin in a 3D Printer

Generally, standard desktop 3D printers are not compatible with epoxy resin. Epoxy resin has a different consistency and requires different curing conditions than the resins used in typical 3D printing processes, such as SLA or DLP. However, some specialized high-end 3D printers may have the capability to work with epoxy-based materials. Always consult your 3D printer manufacturer’s guidelines and recommendations to ensure you use the appropriate materials for your specific printer.

Can I Make My Own Resin Molds

Absolutely! Making your own resin molds is a fantastic way to personalize your creations and unleash your artistic flair. By using a combination of 3D design software and a 3D printer, you can bring your unique mold designs to life. This opens up a world of possibilities for custom shapes, sizes, and even intricate details that will make your resin creations truly one-of-a-kind.

Can You 3D Print Seals

Yes, you can 3D print seals using specialized materials such as rubber-like filaments or resins. These materials mimic the properties of rubber and can create functional seals for various applications. Whether you need a seal for a mechanical project, plumbing, or other sealing needs, 3D printing can provide a cost-effective and customizable solution.

Does Resin Stick to PETG

Resin does not typically stick to Polyethylene Terephthalate Glycol (PETG) due to its low viscosity and non-reactive nature. However, for certain applications where resin adhesion is desired, surface preparation techniques such as sanding or coating the PETG surface with a primer can enhance resin adhesion. Always remember to test on a small area before applying resin to a larger PETG surface.

Can I Use Hot Glue Instead of Resin

While hot glue can be a versatile adhesive, it is not a suitable substitute for resin in most cases. Resin offers unique properties, such as transparency, hardness, and smoothness, which cannot be replicated with hot glue. Additionally, hot glue may not provide the same level of durability and longevity as resin. Stick to resin when you need the specific characteristics it offers in your projects.

What Material is Best for Resin Molds

Several materials can be used to create resin molds, depending on your specific needs and preferences. Common choices include silicone, urethane rubber, and even 3D printed molds. Silicone molds are popular due to their flexibility, ease of use, and ability to capture intricate details. Urethane rubber molds offer durability for repetitive casting and can withstand a range of materials. 3D printed molds provide customization and intricate designs. Consider your project requirements and choose the material that best fits your needs.

Is Casting Additive Manufacturing

No, casting and additive manufacturing are different processes. Casting, as the name suggests, involves pouring a material into a mold and allowing it to solidify. Additive manufacturing, or 3D printing, builds objects layer by layer using materials like filaments or resins. While both methods are valuable manufacturing techniques, they differ in approach and application. Casted objects are commonly used for mass production, while 3D printing offers more flexibility and customization options.

Can You 3D Print Metal Parts

Yes! 3D printing metal parts has become increasingly popular in recent years. Specialized metal 3D printers use techniques such as Selective Laser Melting (SLM) or Bound Metal Deposition (BMD) to create metal objects. While these printers can be expensive and require specific equipment, they allow for the production of complex and precise metal parts that were once challenging to manufacture using traditional methods.

Can You Mix Acrylic with Resin

Mixing acrylic with resin is possible and can create interesting effects, such as a translucent or glittery finish. However, it’s essential to ensure compatibility between the specific type of acrylic and resin you are using. Always test a small amount before mixing large quantities to ensure the desired result and to avoid any adverse reactions between the materials.

How Do You Keep Silicone from Sticking to Silicone

When working with silicone, it’s important to prevent it from sticking to itself, especially when creating multi-part molds. To achieve this, you can use a silicone release agent or a mold release spray. These products create a barrier between the silicone surfaces, preventing them from bonding together. Be sure to follow the manufacturer’s instructions for the specific release agent you choose.

Can I Use 3D Printer Resin for Casting

Yes, 3D printer resin can be used for casting, but it may not offer the same properties as specialized casting resins. While some printer resins are formulated to be both printable and castable, others may have limitations when used for casting due to their curing properties. It’s essential to check the compatibility and suitability of your specific resin for casting purposes before proceeding.

What Kind of Silicone is Used for Molds

Silicone molds are commonly made from two-part silicone rubber compounds. These compounds cure at room temperature or with the addition of a curing agent. There are various types of silicone rubbers available, such as tin-cured (condensation cure) or platinum-cured (addition cure). Platinum-cured silicone offers better dimensional stability and avoids potential issues with sulfur-based materials. Choose a silicone mold material that suits your project requirements and consult the manufacturer’s recommendations for proper usage.

How Do I Print Smooth Resin

To achieve smooth resin prints, several factors come into play. First, ensure your 3D printer is properly calibrated to achieve precise layer heights and accurate print settings. Additionally, post-processing techniques, such as sanding, polishing, or using a UV cure chamber, can help achieve a smooth finish. Experiment with different techniques and settings to find the right combination that suits your desired level of smoothness.

Can You Put a Drawing in Resin

Yes! Putting a drawing in resin is a fantastic way to preserve and display your artwork. To do this, simply place your drawing between layers of resin, ensuring it is fully covered. This method encapsulates the drawing and creates a beautiful, transparent effect. It’s a unique way to showcase your creativity and create stunning pieces of art.

Is Resin Stronger than ABS

Resin and Acrylonitrile Butadiene Styrene (ABS) are different materials with unique properties. Generally, resin offers greater strength and rigidity compared to ABS. Resin prints have fewer visible layers and smoother surfaces, which can contribute to their overall strength. However, it’s important to note that the specific characteristics of resin and ABS can vary depending on the brand and formulation, so always consider the specific requirements of your project.

Is 3D Printed Metal as Strong as Forged

While 3D printed metal objects have come a long way in terms of strength and durability, they are not yet on par with traditionally forged metal objects in terms of overall strength. Forged metal objects, which undergo a process of shaping and compressing metal through extreme heat and pressure, still tend to have superior strength properties. However, additive manufacturing techniques continue to evolve, and 3D printed metal objects can offer highly complex geometries and customized designs that are difficult to achieve with traditional forging methods.

What is Silicone Printing

Silicone printing refers to the process of using specialized printers and silicone-based materials to create objects made primarily of silicone. These printers operate differently from standard filament-based printers and can produce silicone-like objects by extruding or jetting silicone-based materials. Silicone printing offers unique possibilities for creating customized silicone-based products, such as medical devices, soft robotics, and more.

Can You 3D Print Cast Iron

While it’s not currently possible to directly 3D print cast iron using standard desktop 3D printers, there are metal 3D printing processes that can produce cast iron-like objects. These specialized printers use metal powders or filaments infused with binders and then undergo post-processing, such as sintering or heat treatments, to achieve the final cast iron-like properties. However, this technology is still relatively new and primarily used in industrial applications.

Can You 3D Print TPE

Yes! 3D printing with Thermoplastic Elastomers (TPE) is possible using specialized filament-based printers capable of handling flexible materials. TPE is a type of rubber-like material known for its stretchability and durability. Printing with TPE can open up opportunities for creating flexible objects such as gaskets, shoe soles, phone cases, and more.

What is the Best Material for Making a Mold

The best material for making a mold depends on several factors, including the desired level of detail, the intended casting material, and the expected number of uses. Silicone molds are versatile, easy to use, and can capture intricate details. Urethane rubber molds offer durability and are suitable for repeated castings. 3D printed molds allow for customization and complex designs. Consider your specific project requirements and choose a mold material that best suits your needs.

Is Casting a Type of 3D Printing

Casting and 3D printing are two distinct manufacturing processes. Casting involves pouring a material into a mold and allowing it to solidify, resulting in a final object. In contrast, 3D printing, or additive manufacturing, builds objects layer by layer using materials such as filaments or resins. While both methods have their advantages and applications, they differ in approach and capabilities.

Can I 3D Print a Mold for Resin

Absolutely! 3D printing a mold for resin is an excellent way to create custom shapes and sizes for your resin casting projects. By designing a mold and 3D printing it, you have full control over