Have you ever wondered how to add weight to your 3D prints? Whether you’re looking for increased durability or a more substantial feel, there are several techniques you can use to make your prints heavier. In this blog post, we’ll explore different methods to achieve a weightier 3D print, along with tips to enhance the overall strength and density.

From adjusting printing parameters to selecting suitable materials, we’ll cover everything you need to know to make your 3D prints more substantial. But before we dive in, let’s address some common questions related to 3D printing, such as the strength of different materials, the impact of temperature, and the importance of infill. So, if you’re ready to take your 3D printing game to the next level, let’s get started!

How to Make Your 3D Print Weightier

Have you ever looked at your 3D prints and thought, “Gee, these babies need a little more weight”? Well, you’re in luck! In this subsection, we’ll explore some ingenious ways to add substance and heft to your 3D prints. Prepare to take your creations from lightweight to weight lifter!

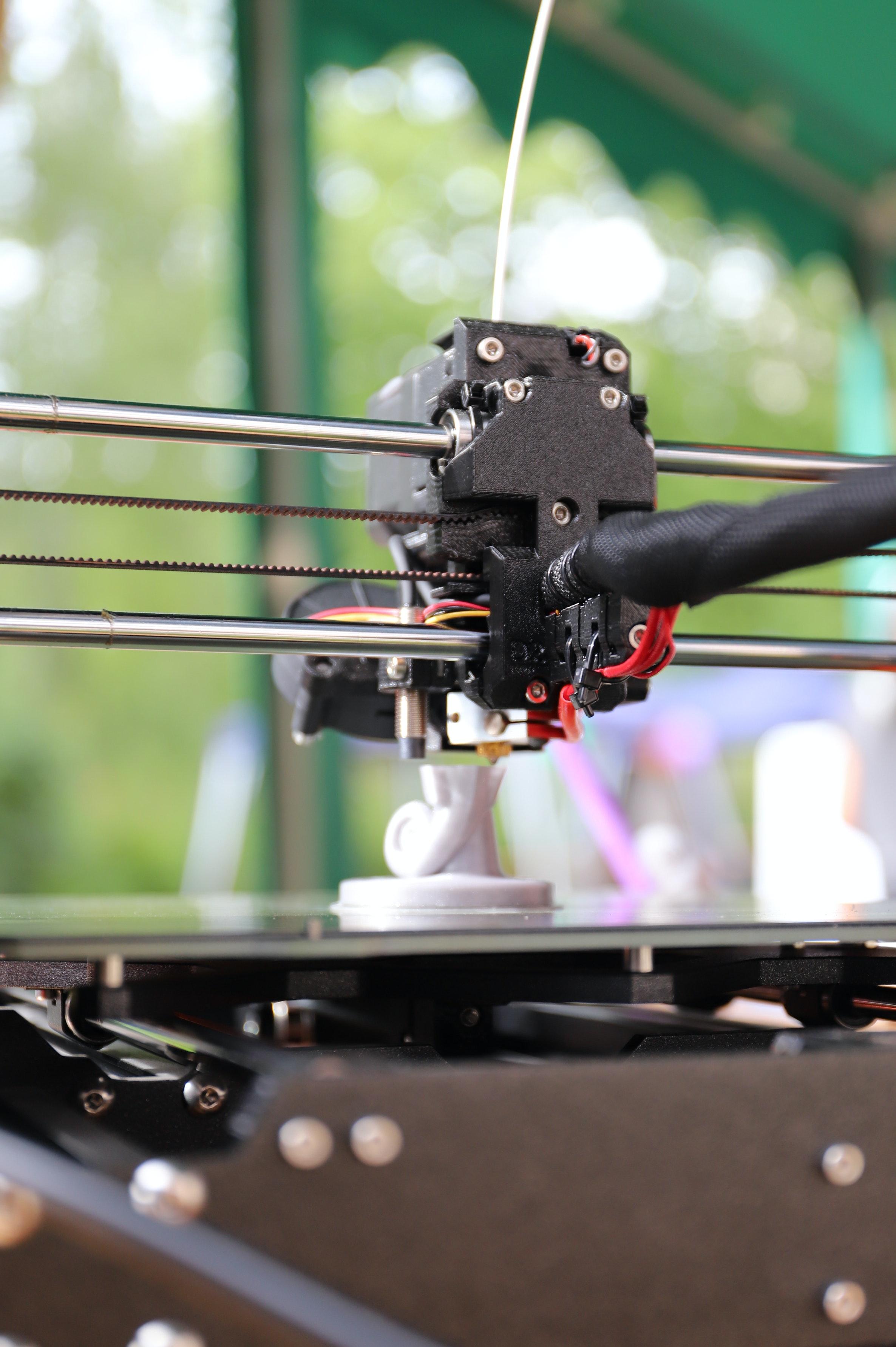

Bulk Up with Extra Layers

One way to give your 3D prints some extra gravitas is by adding more layers to the design. By increasing the layer height, you effectively increase the amount of filament used, which in turn adds weight to your print. It’s like hitting the gym for your creations!

Embrace the Magic of Infill

Infill, that secret ingredient in 3D printing, can also help you in your quest for a heavier print. Increasing the infill density will add more material inside your print, contributing to a denser and weightier final product. Time to flex those infill muscles and make your prints shine!

Time to Get Dense

Speaking of density, tweaking the density settings can make a significant difference in the weight of your 3D prints. By increasing the density, you cram more material into the same volume, resulting in a bulkier and more substantial print. It’s all about that 3D print pump!

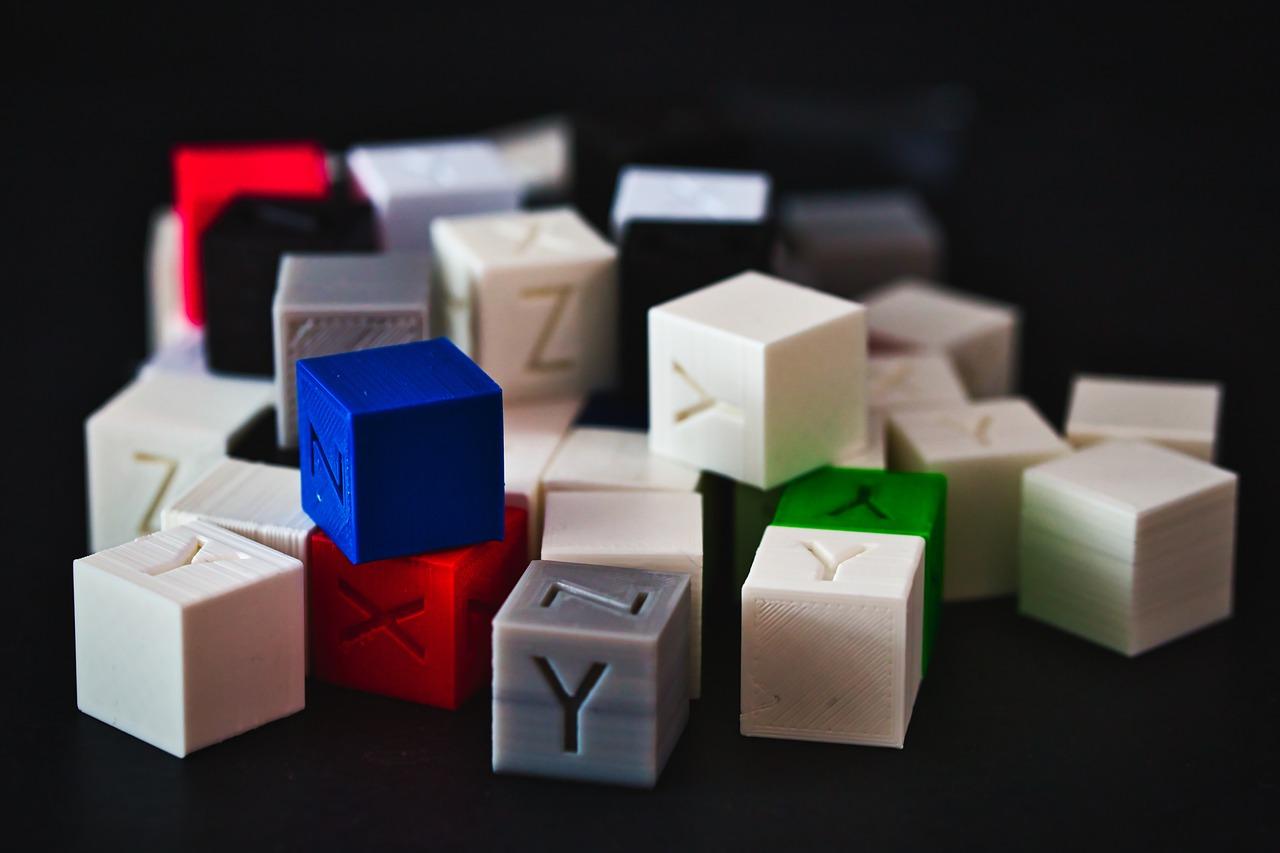

Choose Weighty Materials

The choice of filament can play a crucial role in how hefty your 3D prints feel. Opting for denser materials such as PLA or ABS can add some satisfying weight to your creations. Plus, these materials are known for their strength, so you’ll be killing two birds with one stone (not literally, of course).

Adding Fillers? Why Not!

If you really want to push the boundaries of weightiness, consider adding fillers to your filament. Things like metal powder or glass fibers can be mixed with your filament to make it denser and, consequently, make your prints heavier. Who said 3D printing couldn’t be an extreme sport?

Give It a Good Sanding

No, we’re not talking about a day at the beach here. Sand-ing your 3D prints can actually make them heavier. By sanding down the outer layers, you are effectively removing material and reducing the size of your print. This in turn increases the weight-to-volume ratio, giving your prints a satisfying heft.

Don’t Be Afraid to Overdo It

If all else fails, don’t be afraid to go a little overboard with your designs. Remember, we’re aiming for weight here! Consider adding decorative elements or unnecessary but delightful embellishments to bulk up your prints. Go big or go home, right?

Congratulations! You’ve now mastered the art of making your 3D prints weightier. With these tips and tricks up your sleeve, you can take your creations to the next level, impressing friends and strangers alike with the stunning weight and presence of your prints. Let’s leave lightweight in the past and embrace the power of solid and substantial 3D printing!

FAQ: How to Make a 3D Print Heavier

So, you’re looking to add some extra weight to your 3D prints? Whether you’re building a model that needs a little more heft or you simply want a sturdier finished product, we’ve got you covered. In this FAQ-style subsection, we’ll answer some common questions about making your 3D prints heavier and stronger.

What Happens if You Print PLA Too Hot

Printing PLA too hot can lead to a host of problems, but when it comes to making your 3D prints heavier, overheating PLA isn’t the solution. In fact, printing PLA at higher temperatures can result in a weaker print with reduced layer adhesion. Stick to the recommended temperature range for PLA to ensure optimal print quality and strength.

Is PETG Better Than PLA

When it comes to strength and durability, PETG has the upper hand over PLA. PETG prints are not only more impact-resistant but also have higher temperature resistance. So, if you’re aiming for heavier and sturdier prints, consider making the switch to PETG. Your creations will be ready to take on the world!

Is PLA Stronger Than Wood

While PLA is a versatile material, it falls short when compared to the strength of wood. Wood filament can be a game-changer if you’re looking to make your prints heavier and more robust. With wood-infused PLA, you can achieve a natural, textured finish while enjoying the added strength and density this filament provides.

Is Resin or PLA Stronger

When it comes to sheer strength, resin takes the lead over PLA. Resin prints boast superior structural integrity and are less prone to breakage. However, if you’re focused on making your 3D prints heavier, PLA still has its merits. PLA prints tend to be denser, so don’t hesitate to experiment with different materials to strike the perfect balance between weight and strength.

Does Infill Increase Strength

Infill plays a significant role in determining the strength and weight of your 3D prints. Increasing the infill percentage will make your prints heavier as more material is used. However, it’s important to find the right balance, as increasing infill percentage significantly beyond the recommended range may not have a substantial impact on strength but will add unnecessary weight and printing time.

How Do You Strengthen Hollow 3D Prints

Making hollow prints heavier while maintaining their structural integrity is a challenge. One way to strengthen hollow prints is by increasing the wall thickness. This can be achieved by adjusting the number of perimeters in your slicer settings. Adding more perimeters will result in a denser print, reinforcing its overall weight and strength.

What Layer Height is Strongest

When it comes to layer height, thinner isn’t always better for making heavier prints. A layer height of around 0.2mm is generally considered a good balance between print quality and strength. While a smaller layer height can enhance details, it might compromise the overall strength of your print.

How Strong is 50% Infill

Fifty percent infill is a sweet spot for striking a balance between weight and strength in your prints. With half the space filled, your print gains substantial structural integrity without becoming unnecessarily heavy. So, if you’re aiming for a perfect balance, 50% infill is a great choice!

What is the Strongest 3D Infill

When it comes to creating a heavy-duty 3D print, the gyroid infill pattern takes the crown. Its intricate structure provides optimal strength while minimizing weight. The gyroid infill is like the secret weapon in your arsenal, allowing you to create prints that are both solid and strong.

What Temperature Should the Bed Be for PLA

To achieve the best results with PLA prints, a bed temperature of around 60°C is generally recommended. This helps ensure proper adhesion and prevents warping. So, keep things cozy on the print bed and your PLA prints will come out strong and secure.

Will PLA Melt in the Sun

While PLA has a relatively low melting point compared to other materials, it won’t melt under normal sunlight exposure. So, feel free to showcase your PLA prints in the sun without worrying about them turning into a colorful puddle. PLA will hold its ground and retain its weighty goodness.

How Can I Make My 3D Printer More Dense

If you’re planning to increase the density of your 3D prints, there are a few tricks up our sleeves. Firstly, you can adjust your slicer settings to increase the infill percentage. Additionally, using a higher number of shells and thicker layers can add density to your prints. Experiment with these settings to achieve the perfect balance between weight and strength.

Is 20% Infill Strong Enough

While 20% infill may suffice for certain applications, it’s important to consider the intended use of your print when determining infill strength. If you’re looking for a lightweight and functional print, 20% infill should work fine. However, if you’re aiming for heavier and sturdier prints, consider increasing the infill percentage for added strength.

Why Are My 3D Prints Weak

Weak 3D prints can be the result of several factors. Common culprits include incorrect slicer settings, inadequate cooling, incorrect filament temperature, or poor adhesion. By fine-tuning these variables and ensuring proper printer calibration, you can overcome the weakness and achieve the strong, robust prints you desire.

What Happens if the Nozzle is Too Close to the Bed

When your nozzle is too close to the bed, it can lead to poor adhesion and weak prints. This occurs because the filament is compressed too tightly against the build surface. To avoid this, make sure to level your bed properly and maintain a slight gap between the nozzle and bed. Your prints will come out stronger and more reliable.

Does Epoxy Make 3D Prints Stronger

Epoxy can be a secret weapon for reinforcing and strengthening your 3D prints. By applying epoxy to the surface of your print, you can add an extra layer of protection and durability, enhancing its strength. Additionally, epoxy can fill in minor imperfections, resulting in a smoother and more polished finish.

Why Are My 3D Prints Rough

Rough 3D prints can be a buzzkill, but fear not! The roughness may be due to issues like incorrect layer height, inadequate infill, improper cooling, or poor filament quality. Fine-tuning your printer settings, using higher infill percentages, ensuring proper cooling, and opting for high-quality filament can help you smooth out those rough edges and achieve quality, weighty prints.

Is 100% Infill the Strongest

You might think that 100% infill would make your prints the strongest. However, it’s not always the case. While it does make your prints dense, the incremental increase in strength isn’t always significant compared to the added weight. Instead, consider using optimized infill patterns, like the gyroid infill, to strike the right balance between weight and strength.

How Do You Make PLA Prints Stronger

To make your PLA prints stronger, consider adjusting some parameters. Increasing the number of shells and the infill percentage will add density and strength to your prints. Additionally, experimenting with different materials, such as wood-infused PLA, can enhance the overall robustness of your creations. So, let your imagination soar and produce prints that are heavyweights in the 3D world!

With these FAQs, you’re now armed with the knowledge to make your 3D prints heavier and sturdier. From adjusting infill percentages to exploring different filament options, the power is in your hands. So, go forth and create prints that are weighty, strong, and ready to tackle any challenge! Happy printing!

Note: This blog post was written for the year 2023.