Creating a 3D printer prototype can be an exciting and innovative endeavor, but it’s important to understand the costs involved. In this blog post, we will explore the various factors that contribute to the overall cost of building a 3D printer prototype. From the initial design and development stages to the materials and equipment required, we will break down the expenses and provide you with an estimate of how much it may cost to bring your 3D printer prototype to life.

Whether you’re a DIY enthusiast or an inventor looking to transform your idea into a tangible product, understanding the financial implications of prototyping is key. We will also delve into the potential returns on investment and explore how inventors can earn royalties from their prototypes. So, if you’re curious about the costs, timelines, and considerations involved in creating a 3D printer prototype, keep reading!

How Much Does it Cost to Create a 3D Printer Prototype

Calculating the Price Tag

When it comes to bringing a 3D printer prototype to life, one burning question keeps many enthusiastic innovators awake at night: “How much is this going to cost me?” Well, fear not, fellow inventors, for we’re about to embark on a cost analysis adventure that will demystify the ins and outs of creating a 3D printer prototype. So, grab your calculators, sharpen your pencils, and let’s dive right in!

The Almighty Budget Breakdown

Research and Development

Ah, the exhilarating realm of research and development (R&D)! This is where the magic happens, folks. In this phase, you’ll be exploring designs, testing various components, and battling against setbacks like a valiant knight. And, of course, this quest doesn’t come without a price tag. On average, you’ll need to set aside a sizable chunk of your budget – typically between $5,000 and $20,000 – for R&D, depending on the complexity and scale of your 3D printer prototype.

Hardware Heroes

Assembling the hardware for your 3D printer prototype requires a keen eye for quality and a knack for snagging the best deals. The cost of hardware components can vary widely, but a ballpark figure for a basic model hovers around $1,000 to $5,000. Keep in mind that premium features, like higher print resolution or larger build volume, will naturally drive up the price.

Software Sorcery

Now, it’s time to sprinkle a little software magic onto your 3D printer prototype masterpiece. To breathe life into your creation, you’ll need slicing software – the virtual wizard that transforms your digital 3D models into printable layers. Fear not, my friends, for there are many free or affordable slicing software options readily available. However, for the sake of an accurate cost estimate, let’s allocate around $500 to $1,000 for this vital piece of the puzzle.

Electrical Essentials

Power up! Electrical components are the lifeblood of any 3D printer prototype. From motors to heating elements to control systems, these essential elements keep your printer humming along. Depending on the complexity of your design, you’ll need to allocate around $500 to $2,000 for electrical components. Don’t forget to budget for some extra cables and connectors, just in case. Safety first!

The Devil’s in the Details

Miscellaneous Must-Haves

Attention to detail should be your middle name. While it’s impossible to predict every single expense, there are a few miscellaneous items that tend to sneak up on unwary inventors. These could include tools, adhesives, fasteners, and maybe even a dash of paint to give your prototype that extra flair. Allocate a modest sum of $200 to $500 for these little surprises.

Time is Money, My Friend

Last but not least, we must address the quintessential cost factor that often gets overlooked – your time! Let’s face it, dear inventors, time is indeed money. Whether you’re tinkering away in your garage or working with a dedicated team, the hours add up. Be sure to account for your time investment when calculating the overall cost of creating a 3D printer prototype. After all, your creative brilliance deserves its fair share of recognition!

The Final Verdict

And there you have it, ladies and gentlemen – a comprehensive breakdown of the costs involved in creating a 3D printer prototype. From the perilous realm of R&D to the magical world of software sorcery and electrical essentials, each step along the way demands its own slice of the budget pie. So, dear inventors, before you embark on your 3D printing odyssey, arm yourself with the knowledge of what to expect on the financial front. May your prototypes be flawless and your budgets be well prepared!

FAQ: How Much To Create A 3D Printer Prototype

Welcome to our FAQ-style guide on the cost of creating a 3D printer prototype. In this section, we will address some common questions that arise when it comes to the expenses involved in building a 3D printer prototype. From the cost of building a DIY printer to the overall product development expenses, we’ve got you covered!

How much does it cost to build a prototype

The cost of building a prototype can vary depending on various factors such as complexity, materials, and manufacturing method. On average, the cost can range from a few hundred dollars to several thousand dollars. It’s important to consider not only the initial prototype cost but also potential revisions and improvements that may be needed.

How much does it cost to build a DIY 3D printer

Building your own 3D printer can be an exciting and cost-effective option. The cost of building a DIY 3D printer largely depends on the components you choose and the level of customization you desire. A basic DIY kit can start from around $200, while more advanced setups with additional features can go up to $1,000 or more.

How much do inventors make on royalties

Royalties earned by inventors can vary significantly depending on factors such as the success of the product, the market demand, and the licensing agreement. The royalty percentage typically ranges from 2% to 10%. However, it’s important to remember that inventors often have additional expenses, such as patenting and marketing, that can impact their overall earnings.

Is 3D printing expensive

While 3D printing has become more accessible over the years, it’s essential to weigh the costs against the benefits. The price of 3D printing can vary based on factors like the complexity of the design, size, and material used. Generally, 3D printing can be cost-effective for small-scale production or custom manufacturing, but it may not always be the most economical option for large-scale mass production.

How much does a custom 3D printer cost

Custom 3D printers can be an excellent investment for businesses or individuals with specific needs. The cost of a custom 3D printer can range from a few thousand dollars to tens of thousands of dollars, depending on the desired features and specifications. If you have unique requirements that cannot be fulfilled by off-the-shelf models, a custom 3D printer might be the way to go – but be aware of the associated costs.

How do I turn my idea into a prototype

Turning an idea into a prototype involves several steps. Firstly, you need to conceptualize and design your product. Then, you can create a virtual model using computer-aided design (CAD) software. Once the design is finalized, you can proceed to build a physical prototype using either traditional manufacturing methods or 3D printing. Collaboration with experts in product development can help streamline this process.

How long does it take to make a prototype

The time it takes to create a prototype depends on several factors, including the complexity of the design, the chosen manufacturing method, and the availability of resources. It can range from a few days to several weeks or even months. To minimize delays, it’s crucial to have a clear understanding of the design requirements, proper communication with manufacturers, and realistic time expectations.

How much is a Formlabs

Formlabs is a well-known manufacturer of high-quality desktop 3D printers. The price of Formlabs printers can vary depending on the model and features. As of 2023, their range of printers starts from around $3,500 and can go up to $10,000 or more for professional-grade setups. Investing in a Formlabs printer can be a great choice for those looking for precise and reliable 3D printing capabilities.

How much does a stereolithography printer cost

Stereolithography (SLA) printers are known for their high accuracy and smooth surface finishes. These printers use a resin-based printing process. The cost of an SLA printer varies depending on the brand, specifications, and size. As of 2023, a high-quality SLA printer can range from $1,500 for entry-level models to over $10,000 for advanced systems used in industries like dentistry and jewelry.

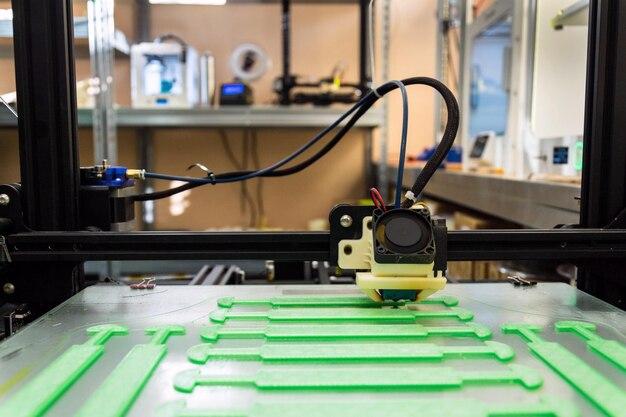

Can 3D printers produce prototypes

Absolutely! 3D printers are widely used for prototyping due to their versatility and cost-effectiveness. Whether you need a quick proof-of-concept model or a functional prototype, 3D printing can bring your ideas to life. It allows for the production of complex geometries and enables iterative design improvements. Remember, 3D printing is not limited to just prototypes; it can also be used for small-scale production.

How much does it cost to run a 3D printer per hour

The cost of running a 3D printer per hour depends on multiple factors, including the electricity rate and the type of filament or resin used. On average, the electricity consumption of a 3D printer ranges from 50 to 250 watts per hour. Considering typical electricity rates, the cost can range from a few cents to a couple of dollars per hour. Be sure to factor in the cost of consumables like filament or resin as well.

How much should product development cost

Product development costs can vary widely depending on the complexity of the product and the chosen manufacturing method. It is challenging to provide a specific cost without specific details. However, as a general guideline, product development can range from several thousand dollars for simple projects to hundreds of thousands of dollars for complex and highly engineered products. It’s essential to budget and plan accordingly.

How much electricity do 3D printers use

The electricity usage of a 3D printer varies depending on factors such as printer model, printing settings, and duration of usage. On average, a 3D printer consumes around 0.05 to 0.25 kWh of electricity per hour. To determine the overall electricity expense, you can multiply the hourly consumption by your electricity rate or refer to your electricity bill for a clearer picture.

How long does it take to assemble a 3D printer

The assembly time of a 3D printer depends on the complexity of the model and the individual’s experience with assembling electronics. A basic kit can typically be assembled in a few hours, while more advanced kits may require a day or two. It’s important to carefully follow the instructions provided by the manufacturer and allocate sufficient time for the assembly process.

Is 3D printing rapid prototyping

Yes, 3D printing is often considered a rapid prototyping technique due to its ability to quickly produce physical models and prototypes. Compared to traditional manufacturing methods, which can take weeks or even months, 3D printing allows for faster iterations and design refinements. Its speed and flexibility make it a valuable tool for engineers, designers, and inventors looking to accelerate the product development cycle.

How much does it cost to design and manufacture a product

The cost of designing and manufacturing a product can vary significantly based on factors like complexity, size, materials, and production volume. Expenses include design fees, prototyping costs, tooling expenses, raw material costs, and manufacturing overheads. It is challenging to provide a specific cost without project details, but it typically ranges from a few thousand dollars for simple products to millions of dollars for complex, large-scale production.

Can I make a product with a 3D printer

Yes, 3D printers are capable of producing a wide range of products, from simple trinkets to functional prototypes and even end-use parts. However, it is essential to consider factors like the size of the product, the chosen printing technology, and the material limitations of the printer. While 3D printing offers great flexibility, certain projects may require other manufacturing methods for optimal results.

How do I patent an idea with no money

Obtaining a patent can be a costly process, but there are options available for inventors with limited financial resources. One option is to prepare and file a provisional patent application, which offers temporary protection at a lower cost. Another approach is to explore pro bono legal assistance programs or seek advice from small business development centers or inventor clubs. Remember to thoroughly research and understand the patent process to protect your idea effectively.

Why are prototypes so expensive

Prototypes can be costly due to various factors. First, the development and design stages require time, skilled labor, and resources. Second, the cost of raw materials and specialized tools used to create prototypes can be significant. Additionally, the iterative nature of prototyping often involves multiple revisions and adjustments, increasing overall expenses. While prototypes may seem expensive, they serve as vital tools for optimizing the design and ensuring a successful final product.

What type of printer manufacturers use for prototyping a new product

Manufacturers often use a variety of technologies for prototyping new products, including 3D printing, CNC machining, injection molding, and vacuum casting. The specific choice depends on factors such as desired material properties, geometrical complexity, production volume, and time constraints. 3D printing is particularly popular in the early stages of product development due to its versatility, cost-efficiency, and the ability to quickly validate designs.

How do you sell an idea to a company without them stealing it

Protecting your idea while presenting it to a company requires careful steps. Start by documenting and keeping records of your idea, including sketches, design files, or any relevant information that proves your ownership. If possible, consider filing for a provisional patent to establish your rights. When negotiating with a company, use non-disclosure agreements (NDAs) to ensure confidentiality. It’s essential to work with reputable companies and consult with legal professionals to safeguard your intellectual property.