Carborundum, a word that may sound unfamiliar to many, is a remarkable substance with a wide range of applications. In this blog post, we will delve into the world of carborundum, exploring its origin, properties, and manufacturing process. We will also answer some common questions, such as whether carborundum is man-made, if it’s safe to use, and how it compares to other materials like diamond. So, if you’ve ever wondered about the intriguing aspects of carborundum and its role in various industries, stay tuned! By the end of this post, you’ll gain a deeper understanding of this fascinating material and its significance in our everyday lives.

Keywords: carborundum, silicon carbide, manufacturing process, properties, origin, applications

How Carborundum Conquers the World

Carborundum, a fascinating material that sounds like a fancy car accessory or a secret weapon in a superhero movie, is actually a synthetic compound with numerous industrial applications. But have you ever wondered how carborundum is made? Prepare yourself for an enlightening journey into the world of carborundum production as we unravel its secrets!

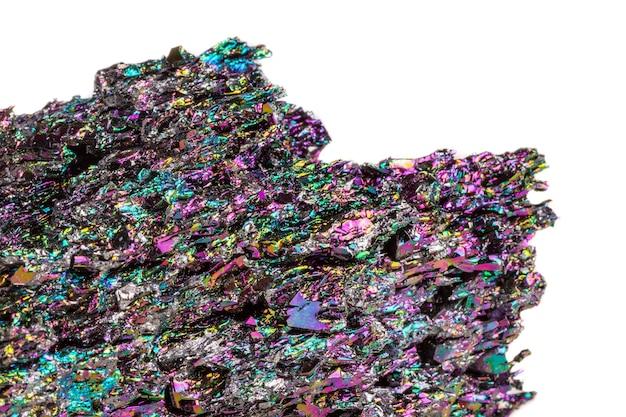

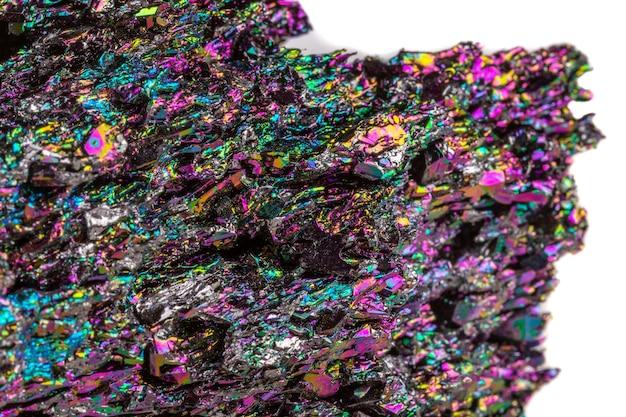

The Birth of a Sparkling Crystal

Carborundum, also known as silicon carbide, is crafted through a process that blends together sand, coke, and a dash of mind-boggling science. These three ingredients embark on a transformational adventure, the result of which is a sparkling crystal that has become an indispensable part of our modern lives.

The Recipe: Sand, Coke, and a Pinch of Magic

First, sand and coke take center stage in this alchemical recipe. Think of them as the dynamic duo of carborundum production. You might be wondering where the magic comes in – well, it’s in the form of electricity.

Electric Dreams: High Voltage and Extreme Heat

In giant furnaces, the mixture of sand and coke is exposed to high voltage electricity. With temperatures reaching over 2000°C (3632°F), these furnaces turn into molten infernos. It’s like a scene out of a sci-fi movie, with sparks flying and a mesmerizing glow enveloping the entire process.

The Melting Pot: Sand Becomes a Liquid

Under the scorching heat, the sand and coke blend together, melting into a viscous liquid. This molten concoction is where the real magic happens. It’s like watching a wizard stir their cauldron, except instead of a potion, we get carborundum!

Crystalline Wonder: Solidifying the Magic

As the molten mixture cools down, the magic crystallizes, and carborundum emerges like a phoenix from the flames. These growing crystals are carefully shaped into precise forms and sizes, making them ready for the next phase of their journey.

Polishing the Gem: Refining and Processing

Once the carborundum crystals have solidified, they undergo refining processes to remove any impurities and enhance their properties. This ensures that the resulting material is of the highest quality and ready to conquer the world! So how is this refinement achieved?

Grinding and Polishing: A Touch of Finesse

The carborundum crystals go through grinding and polishing processes, much like a gemstone getting its final shine. This step creates the smooth, lustrous surface that carborundum is renowned for. Just imagine carborundum strutting its stuff on the red carpet, dazzling everyone with its impeccable finish!

Engineers at Heart: Customization and Adaptation

To meet the diverse needs of various industries, carborundum is further customized and adapted. It can be shaped into different forms – from discs and sheets to powders and even abrasive “sandpaper.” This versatility is what makes carborundum a top contender in industries ranging from automotive to electronics.

Carborundum’s Reign: Conquering Industries Far and Wide

Carborundum’s journey doesn’t end with its production. Once it is ready to conquer the world, it finds its way into a multitude of applications. Its unique properties make it a prized addition in industries such as ceramics, abrasives, refractories, and even the world of semiconductors.

Automotive Prowess: Embracing Carborundum’s Grit

In the automotive industry, carborundum’s hardness and resilience make it ideal for creating robust brake pads and clutch plates that can withstand the intense heat and friction of everyday driving. So next time you brake in your car, give a shout-out to good old carborundum for keeping you safe on the road!

Cutting-Edge Technology: Carborundum in Electronics

When it comes to cutting-edge technology, carborundum is right at home. Its properties, including its exceptional thermal conductivity and resistance to high temperatures, make it a vital component in electronic circuits and semiconductors. Without carborundum, our gadgets might not be as smart and sleek as they are today!

A Blast from the Past: Carborundum and Refractories

The world of refractories, which deals with extremely high temperatures, has long relied on carborundum’s fire-resistant nature. From lining furnaces to paving the way for groundbreaking metallurgical processes, carborundum has left its mark in this scorching industry.

Wrapping Up the Carborundum Journey

And so, we reach the end of our adventure into the marvelous world of carborundum production. From the fiery furnaces to the intricate refinement processes, carborundum emerges as a shining gem, ready to conquer industries far and wide. Its versatility, hardness, and resilience have made it an indispensable material in our modern world. So next time you encounter carborundum, whether in your brake pads or your smartphone’s circuits, remember the compelling story behind this remarkable compound.

FAQ: How Is Carborundum Made

Welcome to our FAQ section on the topic of carborundum! We’re here to answer your burning questions about this fascinating material with a touch of humor and a whole lot of information. So, let’s dig in and uncover the secrets of carborundum!

What is Carborundum

Carborundum is a tough and versatile material that is widely used in various industries. It is a compound of silicon and carbon, also known as silicon carbide (SiC). Carborundum is known for its hardness and durability, making it suitable for a wide range of applications.

Is Silicon a Metal

Well, silicon is not your ordinary metal. It falls into the category of metalloids, which have properties of both metals and non-metals. Silicon is a semiconductor, which means it can conduct electricity but not as well as metals like copper or aluminum. So, it’s like a metal with a twist!

Where Does Carborundum Come From

Carborundum is not something you find lying around in your backyard. It’s synthesized through an industrial process. The raw materials, silicon dioxide (commonly found in sand) and carbon, are heated at high temperatures in an electric furnace. This process, called the Acheson process, leads to the formation of carborundum crystals.

Should I Use Water or Oil on My Sharpening Stone

Ah, this is a classic debate! The answer depends on the type of sharpening stone you have. For carborundum stones, it’s best to use oil. The oil helps to lubricate the stone, reducing friction and preventing heat buildup. However, there are water-based sharpening stones available too, so always check the manufacturer’s recommendations.

Is Carborundum Man-Made

Yes, indeed! Carborundum is a man-made material that was first discovered and produced in the late 19th century by Edward Goodrich Acheson. He was trying to find a way to produce artificial diamonds but ended up creating carborundum instead. Talk about a happy accident!

Is Silicon Carbide Natural

While silicon carbide does exist naturally in small quantities, the vast majority of it is produced synthetically. So, it’s kind of like finding a natural unicorn – rare and elusive!

Is Silicon Carbide Expensive

Compared to some other high-performance materials, silicon carbide can be a bit pricey. The production process involves high temperatures and energy consumption, which adds to the cost. But hey, quality comes at a price, right?

What is a Carborundum Stone

A carborundum stone is a sharpening stone made from carborundum crystals. It has a coarse surface that helps to effectively sharpen knives, tools, and other blades. Think of it as a trusty sidekick for all your sharpening needs.

Is Carborundum Harder Than Diamond

Ah, sorry to burst your bubble, but carborundum falls short in the hardness department when compared to diamonds. While carborundum is one of the hardest materials out there, diamonds still hold the crown as the hardest naturally occurring substance on Earth. So, diamonds still rule in terms of hardness!

What is a Carborundum Stone Used For

Carborundum stones are used for sharpening and honing various cutting tools, including knives, scissors, chisels, and even gardening tools. They help restore a sharp edge to dull blades, making your cutting experience smooth and effortless. Say goodbye to squishy tomatoes and hello to precision slicing!

Is Silicon Carbide Safe to Dab Off

No, no, no! We’re not talking about doing the latest dance move here. Silicon carbide is not safe to dab off, my friend. It’s a highly abrasive material that is not meant for direct contact with your delicate skin. So, keep the dabbing for the dance floor!

How Do You Make Silicon Carbide

We know you’re itching to try your hand at making silicon carbide, but hold your horses! The industrial production of silicon carbide involves heating a mixture of sand (silicon dioxide) and carbon in an electric furnace. The intense heat causes a chemical reaction that forms beautiful carborundum crystals. Trust us, leave this one to the professionals!

What is Carborundum Sandpaper

Carborundum sandpaper is sandpaper that uses carborundum crystals as the abrasive material. It’s known for its durability and effectiveness in smoothing and shaping various surfaces. So, if you’re tackling a DIY project or refinishing furniture, carborundum sandpaper might just be your new best friend.

What Happens When You Burn Silicon Carbide

Well, we don’t recommend setting your silicon carbide collection ablaze, but if you do, you’ll witness a fascinating transformation! When silicon carbide burns, it reacts with oxygen in the air to create carbon dioxide gas and silica (silicon dioxide) residue. Science can be both fun and a little smoky!

Is Silicon Carbide Hazardous

In its solid form, silicon carbide is generally considered safe. However, prolonged exposure to airborne silicon carbide particles can cause health issues, particularly affecting the respiratory system. So, it’s always wise to handle and work with it in a well-ventilated area and take necessary precautions. Safety first, folks!

What Grit is a Carborundum Stone

Carborundum stones come in various grit sizes, ranging from coarse to fine. The grit number indicates the size of the abrasive particles embedded in the stone. Lower grit numbers (e.g., 60 or 80) are coarser and suitable for initial sharpening, while higher numbers (e.g., 400 or 600) are finer and ideal for smoothing and honing.

Who Owns Carborundum

Carborundum is currently owned by Saint-Gobain, a French multinational corporation specializing in construction materials. They acquired Carborundum in 1990, adding this remarkable material to their impressive portfolio.

Is Carborundum Toxic

Carborundum itself is not considered toxic or harmful. However, the dust created during the grinding or sanding process may pose risks if inhaled or ingested. So, make sure to wear proper protective gear, such as a mask and goggles, when working with carborundum and keep the dust away from your mouth and nose.

Is Silicon Carbide Bulletproof

Sorry to burst your action-movie bubble, but silicon carbide alone is not bulletproof. However, it is used as a component in some types of bulletproof armor and composite materials. So, while it won’t save you from a direct hit, it plays a role in helping protect our brave men and women in uniform.

What Disadvantage Does Silicon Carbide Have

Even superheroes have their weaknesses, and silicon carbide is no exception. One disadvantage of silicon carbide is its sensitivity to temperature changes. Sudden and extreme temperature variations can cause the material to crack or degrade. So, be gentle with your carborundum creations!

How is Carborundum Manufactured

Carborundum is manufactured through the Acheson process, named after its inventor, Edward Goodrich Acheson. In this process, a mixture of high-purity quartz sand and petroleum coke is heated in an electric furnace. The intense heat breaks down the chemical bonds and triggers the formation of silicon carbide crystals.

Why SiC is Called Carborundum

Ah, the name “carborundum” is a blend of carbon and corundum (a crystalline form of aluminum oxide). It was coined by Acheson as a play on words, combining the two elements in a snappy and memorable way. Hats off to Mr. Acheson for his creativity!

Do Whetstones Need to Be Wet

Yes, indeed! Whetstones, including carborundum stones, work best when wet. The water acts as a lubricant, helping to prevent the stone from clogging and reducing friction. So, don’t be shy – give your whetstone a soak before sharpening!

Is Silicon Carbide Harder Than Diamond

As much as we’d love to crown silicon carbide as the king of hardness, diamonds still hold the title. Diamonds are the hardest naturally occurring substance on Earth, snagging all the bragging rights. So, keep those prized gemstones at the top of the hardness pyramid!

How Do You Clean Carborundum Crystals

Cleaning carborundum crystals is a piece of cake. Simply give them a gentle rinse under running water to remove any dirt or dust. For stubborn stains, you can use a soft brush or toothbrush to lightly scrub the crystal surface. Just remember, don’t brush too hard – carborundum may be tough, but it’s not invincible!

That wraps up our FAQ section on how carborundum is made! We hope you’ve enjoyed this informative and fun-filled journey through the world of carborundum. Until next time, stay sharp and keep those questions coming!